Did you know that SUS304 and SUS316 are the most popular stainless steel that are widely used around the world? It will be extreme difficult to tell the differences between the grades of stainless steel from our naked eye. Both the stainless steel look almost identical to each other and the differences between the two are easy to miss. So, what are the differences between SUS304 vs SUS316?

We will answer that question and discuss different applications where the grades of stainless steel are used below.

What are the Differences Between SUS304 and SUS316 Stainless Steel?

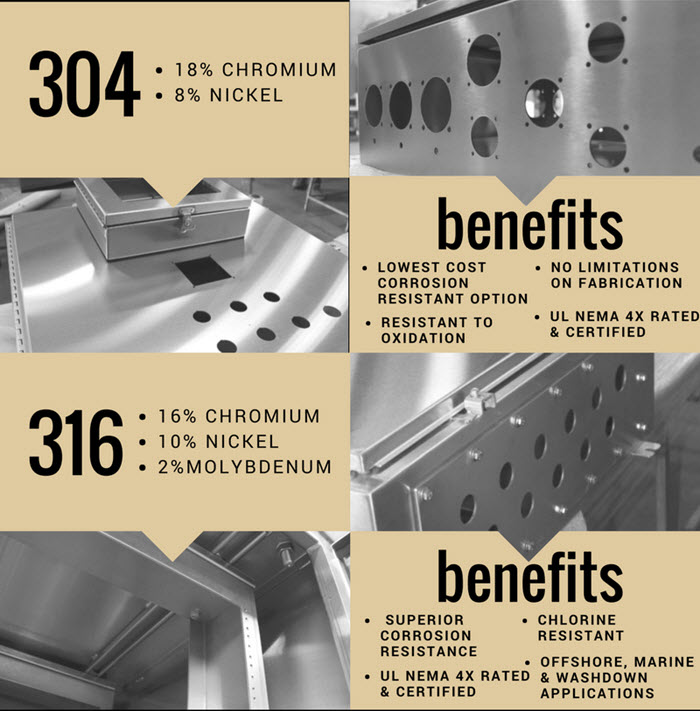

- The most basic difference between SUS304 and SUS316 stainless steels is that SUS316 tends to have more nickel and a bit of molybdenum in the mix compare to SUS304. The general mechanical properties of the two metals are mostly comparable.

- The increase of nickel content and the inclusion of molybdenum allow SUS316 stainless steel to have better chemical resistance compare to SUS304 stainless steel. It’s ability to resist acids and chlorides, including salt, makes SUS316 stainless steel ideal for chemical processing and marine applications.

- The addition of nickel and molybdenum alloy will make SUS316 stainless steel to be more expensive when compare to SUS304 stainless steel.

- The melting point for SUS304 stainless steel will be slightly higher than SUS316 stainless steel. The melting range of SUS316 is between 2,500 °F – 2,550 °F (1,371 °C – 1,399 °C), roughly 50 to 100 degrees Fahrenheit lower than the melting point of SUS304 stainless steel.

- SUS316 stainless steel has a better resistance to chemicals and chlorides (like salt) compare to SUS304 stainless steel. When it comes to applications with chlorinated solutions or exposure to salt, SUS316 stainless steel will be consider to be more superior.

Three Benefits of Using SUS316 Stainless Steel

- Corrosion Resistant Properties

Due to the addition of molybdenum, SUS316 stainless steel is more corrosion resistant than SUS304 stainless steel. This reduces pitting from chemical environments and allows SUS316 stainless steel to be used in highly acidic and caustic environments that would otherwise eat away at the metal. For instance, SUS316 stainless steel can withstand caustic solutions and corrosive applications such as vapor degreasing or many other parts cleaning processes.

These properties also make SUS316 stainless steel ideal for pharmaceutical and medical applications. Since sterilization processes in these industries combine both strong disinfectants and or with high temperatures to prevent contamination, a resistant alloy such as SUS316 is the ideal choice.

- Marine Applications

Seawater and salt air can cause damage to metals. Besides the rough environment of the sea and marine applications, chlorides, such as salt, can eat away at even the toughest metals in the world. Salt will even compromise the protective oxide layer of SUS304 stainless steel which will resulting in rust. For marine applications, or processes involving chlorides, SUS316 stainless steel is ideal.

SUS316 has better resistance to salt and chloride pitting. Pitting corrosion can occur when stainless steel alloys, such as SUS304 stainless steel, come into contact with salt-rich sea breezes and seawater. Chloride resistant metals, like SUS316 stainless steel, are essential to use for naval applications or anything involved with chloride.

- Lasting Durability

SUS316 stainless steel is both tough and versatile, which makes it ideal for custom wire baskets built to last for years of use. This grade of stainless steel can be used to make durable baskets designed to even survived repeated exposure to high impact processes.

Is It Worth the Extra Cost?

If you have an application with very powerful corrosives or relies on chlorides, then paying more for SUS316 stainless steel is definitely worth it because SUS316 stainless will last many times longer than SUS304 stainless steel.

However, for applications using milder acids or where salt exposure is not a concern for you, SUS304 stainless steel can work just fine.